ZMC-1050-S3

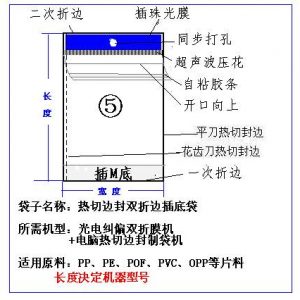

Side center sleeter (2) Out lip flap 3″ (3) Double inside flap 3″ (4) Bottom gassed 3″ (5) Center cutter (6) Single sealing Dai LDPE (7) Single film stand with Air Shaft 74 x 900mm (8) 1.5kw Servo Motor (9) Sick color sensor (Germany).

- Description

Description

Standard Accessories

Side center sleeter (2) Out lip flap 3″ (3) Double in side flap 3″ (4) Bottom gassed 3″ (5) Center cutter (6) Single sealing Dai LDPE (7) Single film stand with Air Shaft 74 x 900mm (8) 1.5kw Servo Motor (9) Sick color sensor (Germany).

Optional Attachment

2/ Two Preheating Sealing

Handel Cut Dai 20 x 80

Invert Flap Sealing

EPC Trolley, (GK-10 & Actuator TD3-90-136)

Powder Break 2.5 kg

2 on one bag (Hole Punch 6 x 75 mm)

Folder with Tapper Tension Control

2nd Servo 1kw

SPECIFICATION:

Max Bag Length: 80~900 mm.

Max Bag Width: 1000.mm

Production Speed with Side Seal: 30 – 190 Pcs/min.

Type of Film: LDPE, LLDPE, HDPE, PP

Machine Dimension (L x W x H): 380 x 180 x 150 cm

Power Required: 8 KW / AC 3800. V 50 Hz.

ACCESSORIES:

| Color Sensor (SICK, Germany) 1 Nos.

AC Servo Motor 1.5KW (Delta, Taiwan) 1 Nos. High Speed Computer (MZH, China) 1 Nos. Handel Cut Dai 20 x 80 1 Nos. EPC Trolley, (GK-10 & Actuator TD3-90-136) 1 Nos. Powder Break 2.5 kg 1 Nos. Folder with Tapper Tension Control 1 Nos. Inverter 0.75 KW (Kewo, China) 2 Nos. Inverter 1.5 KW (Kewo, China) 1 Nos. Anti-Static Transformer And Rod (Pakistan) 1 Set. |