- Description

Description

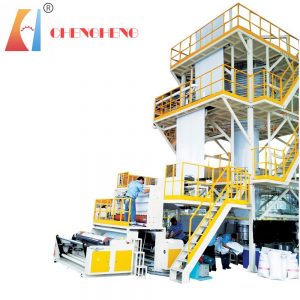

Our company research and development of super high speed film blowing machine, improved more suitable for raw material (secondary recycled materials) base on the Taiwan technology, screw segment compression, shear mixing advanced technology has applied for national patent, good shear and mixing the plastic is fully classified, enhanced the thin film vertically and horizontally tension, as principal of the production increasing, brightness and the feel of the film can meet the demand of bag market.

The whole machine is square structure

Traction inverter control, host frequency conversion control, (optional fan frequency control, winding frequency control) 100% inverter motor + frequency converter control

- Full enclosed over temperature cooling device

- Brand Industrial electricity

- Lambdoidal board

Optional accessories

- AutoLoader

- Corona treater

- Air compressor

- Mechanics screen changer

- Double winding

- 360°Die rotary device

- full-automatic winder and lap changing equipment

| Model

|

G-45-40/700 G-50-45/900 G-55-50/1200 G-65-55/1400 | ||

| Width of the film

(薄膜宽度) |

T-shirt bag(背心袋) | □200-420mm □250-600mm □300-1000mm □500-1200mm | |

| Flat bag(平口袋) | □200-600mm □250-800mm □500-1100mm □500-1300mm | ||

| Thickness of the film(薄膜厚度) | 0.006-0.04mm | ||

| The max output(最大产量) | □85kg/h □125kg/h □150kg/h □175kg/h According to different width, thickness of film, die size and raw material characteristics to change (根据膜宽度、膜厚度、模头大小及原料特性不同而变化) |

||

| Raw material(适用原料) | HDPE/LDPE/LDPE | ||

| Power consumption(耗电量) | □25kw/h □28kw/h □35kw/h □40kw/h | ||

| Weight(重量) | □2800kg □3200kg □3800kg □4200kg | ||

| Overall dimension(L*W*H)m

外形尺寸(长*宽*高) |

□6.5*2.7*5 □6.5*3*5.8 □6.5*3.8*6.2 □6.8*4*6.8 | ||

| Extruder unit(主机部分) | |||

| Diameter of screw

(螺杆直径) |

□Φ45/50 □Φ50/45 □Φ55/50 □Φ65/55 38CrMoALA wear proof Alloy steel,five years guarantee (采用38CrMoALA耐磨合金钢,质保五年) |

||

| L/D ratio of screw

(螺杆长径比) |

30:1 | ||

| Rotation speed of screw

(螺杆转速) |

10-120r/m | ||

| Barrel Fan

(机筒冷风机) |

Zone 3 barrels install over-temperature fan

(机筒3区安装超温风机) |

||

| Gear box(齿轮箱) | □146#×2 □173#×2 □200#×2 □225#×2 Extruder special hard gear reducer,tooth grinding teeth hardened, internal and external oil circulation system (挤塑机专用硬齿面减速机,齿面磨齿淬火处理,内外油循环系统) |

||

| Main motor(主电机) | □11kw □15kw □30kw □37kw×2 100% Original three-phase variable frequency motor Equipped with inverter control (100%正品三相变频调速电机 配装变频器控制) |

||

| Die head unit(模头部分) | |||

| Die diameter

(口模直径) |

□50mm □60mm □80mm □100mm □120mm With 40Cr steel forging finishing, eight feed trough runner,Uniform flow channel,blown plasticizing effect (采用40Cr钢锻打后精加工,8个进料流道槽,流道均匀,吹膜塑化效果好) |

||

| Cool unit(风环类型) | |||

| Air ring type

(风环类型) |

□LDPE double vents vacuum air ring(□HDPE双风口负压风环)

□HDPE Single outlet air ring(□HDPE单风口风环 ) |

||

| Air ring material

(风环材料) |

High-quality Taiwan cast aluminum alloy air ring

(优质台湾铸铝铝合金) |

||

| Bellow power

(鼓风机功率) |

□1.5kw □4kw □2.2kw □7.5kw □11kw Shanghai production of high-pressure mute fan (上海产高压静音风机) |

||

| Traction unit(牵引部分) | |||

| 旋转驱动 | 0.75KW低速电机 | ||

| 气浮换向辊 | 0.5kw漩涡增压风机 ×2 | ||

| 运动方式 | ±350° | ||

| 旋转塔架装置 | 由齿轮组合组成,无死角免维护。 | ||

| Width of take up roller

(夹棍宽度) |

□700mm □900mm □1200mm □1400mm | ||

| Traction roller material

(牵引胶辊材质) |

□silicone roll(□硅胶辊)

□NBR roller(□丁晴胶辊) |

||

| Take up motor

(牵引电机) |

□1.5kw □2.2kw □3.0kw Installation of RV series reducer variable frequency motor inverter control (变频电机加装RV系列减速机 变频控制) |

||

| Take up speed

(牵引速度) |

100m/min | ||

| 恒张力牵引电机 | □1.5kw变频控制□10N.m力矩控制 | ||

| 牵引辊宽度 | □700mm □900mm □1200mm □1400mm | ||

| Embossing roller

(压纹辊机构) |

□hot embossing unit ( □热压纹装置 )

□cold embossing unit (□冷压纹装置) |

||

| Lambdoidal board

(人字夹板) |

Wooden flannel wrapped(木质绒布包裹) | ||

| Gusset equipment

(插边装置) |

□Modular rack type (□组合式齿条式)

□ Independent Split (□独立分体式) |

||

| Bubble stabilizing ring

(稳泡装置) |

□Electric aluminum roller guide (□电动铝导辊 )

□Manual wood floor (□手动木质板) |

||

| Guide roller(导辊) | Aluminum guide roller (HV300-HV700) surface treatment

(铝导料辊 (HV300-HV700)表面处理加工) |

||

| Winding unit(收卷部分) | |||

| Winding type

(收卷方式) |

Surface friction rewinding, manually change the volume

(表面摩擦式收卷,手动换卷) |

||

| Drive type(驱动方式) | Torque motor equipped RV reducer(力矩电机配装RV减速机) | ||

| Film expanding roller(薄膜展开装置) | Smoothing roll(展平辊) | ||

| 二次牵引部分 | 独立力矩控制,恒张力控制 | ||

| Electric control cabinet(电控柜) | low-voltage is Universal electrical appliances, Delixi Electric, Taiwan’s Yang Ming Electric, Huibang temperature control table

(低压电器为环宇电器、德力西电器、台湾阳明电器、汇邦温控表) |

||

| Computer control type(电脑控制系统) | □7-inch touch screen + process control system(□7寸触摸屏+程序控制系统)

□Automatic air supply device (□自动补气装置) |

||